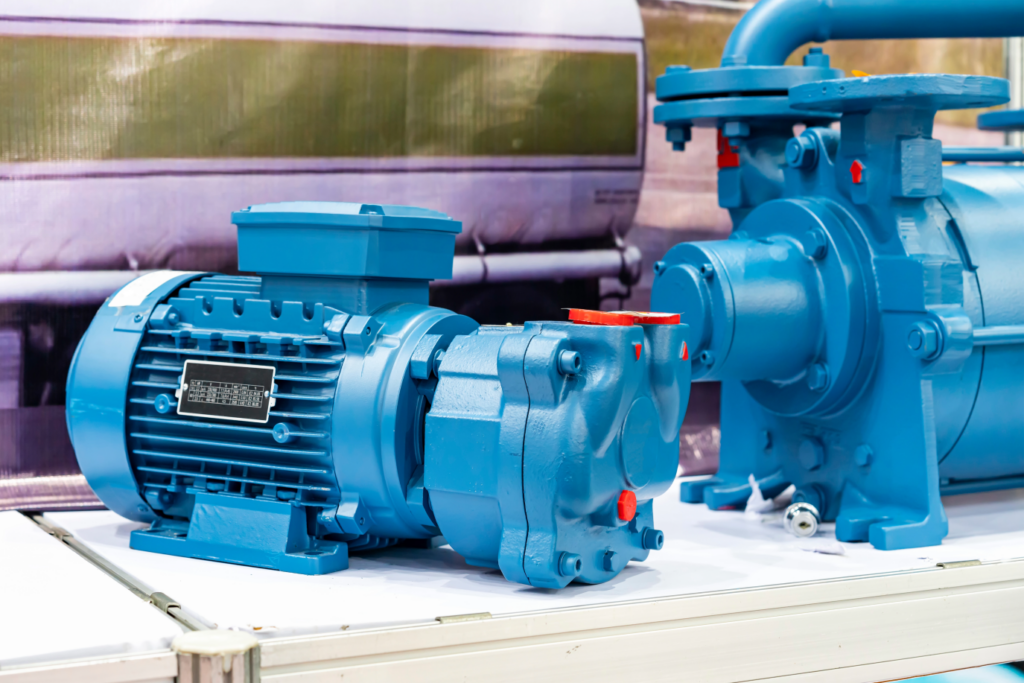

Liquid Ring Pumps

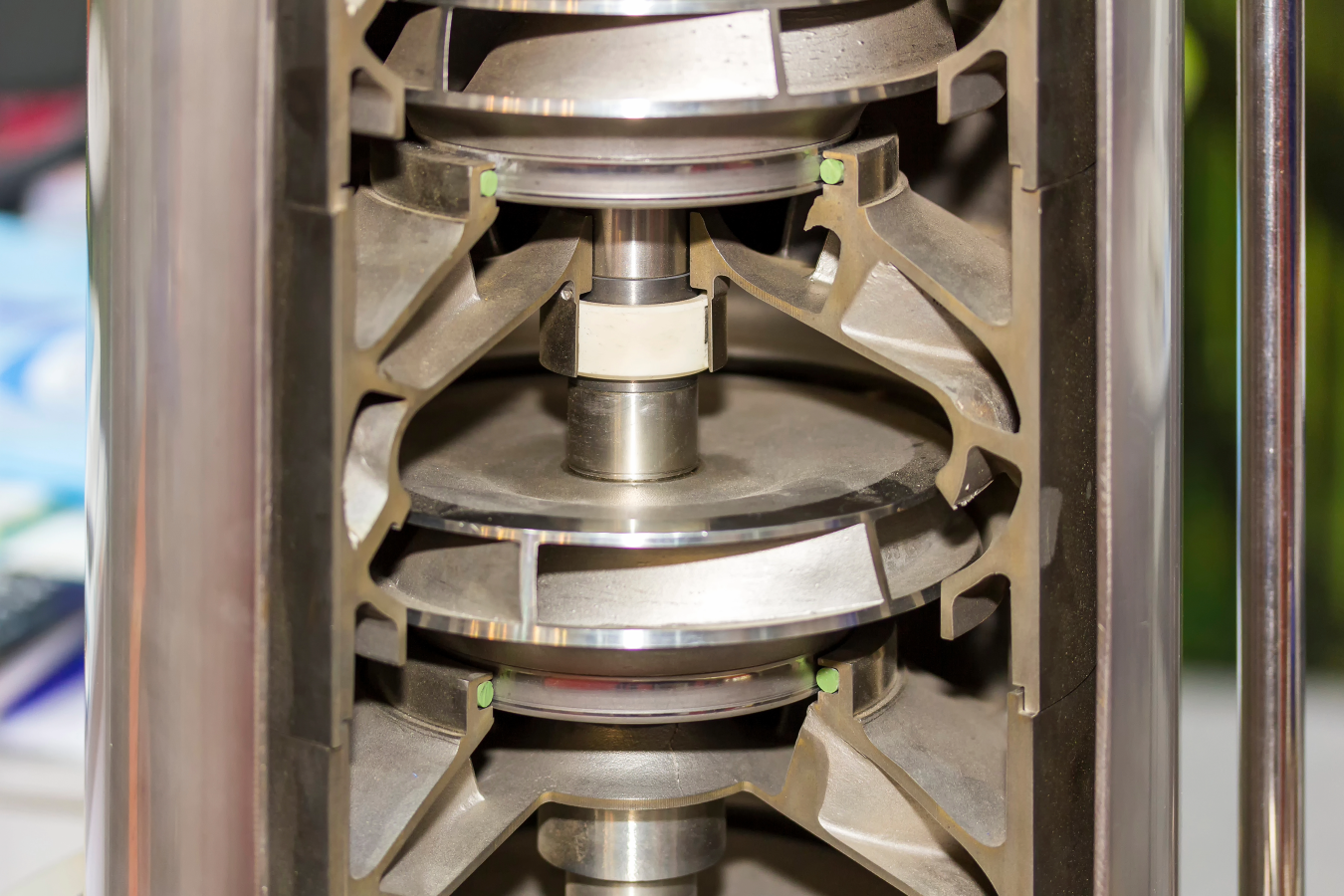

Inside a liquid ring pump, an eccentrically spinning impeller stirs a pool of liquid, forming a swirling ring on the pump's walls. This liquid ring does the heavy lifting, creating pockets that expand and shrink like tiny bellows. As the impeller rotates, these pockets grow near the inlet, sucking in gas like a miniature vacuum cleaner. Then, they travel to the discharge side, shrinking to expel the gas. The liquid ring, acting as both seal and piston, protects the pump's insides from harsh environments while enabling quiet, efficient operation. Because the rotor is the only moving part, maintenance is reduced. OEE Companies can supply both single stage and multi-stage liquid ring vacuum pumps in various materials of construction for a variety of applications. Contact us to get a quote or discuss the technical parameters of your application.

ADVANTAGES OF LIQUID RING PUMPS

- Tolerate liquid carryover

- Quiet, low vibration operation

- Vacuum up to 29″HgV

- Requires little to no maintenance

- Safe for explosive gases

- Mechanical seals are standard

LIQUID TYPES FOR LIQUID RING PUMPS

- Water

- Oil

- Solvents

- Glycols

- Alcohols

APPLICATIONS FOR LIQUID RING PUMPS

- Vacuum forming of molded paper pulp products and plastics

- Plastic extruder for degassing and handling water carryover

- Vacuum distillation

- Vacuum filtration

- Vacuum priming

- Food processing for vacuum massaging and poultry and fish evisceration

- Bottle filling

- Deareation

- Sterilization

- Vapor and solvent recovery

- Condenser exhaust

- Crystallization